XFC | 极速控制技术

I/O 响应时间小于 100 µs

中国区总部

毕孚自动化设备贸易(上海)有限公司

+86 21 6631 2666

info@beckhoff.com.cn

www.beckhoff.com.cn/zh-cn/

I/O 响应时间小于 100 µs

倍福采用 XFC 技术的产品能够满足对快速控制、短响应时间以及微秒级确定性控制有极高要求的应用需求。该技术包含 EtherCAT 现场总线通信系统、高性能工业 PC、IP20 端子盒和 IP67 端子盒等 I/O 产品以及灵活的 TwinCAT 自动化软件。

XFC 技术具有更高的时间分辨率,为精度要求极为严苛的工艺流程带来了显著的优势。得益于优化的控制架构和各种子技术的集成,系统响应时间可远低于 100 微秒。因此,即使采用标准模块,也能以高精度和高可靠性实现高动态的离散控制场景。

XFC 技术包含以下来自不同产品领域的子技术:分布式时钟、时间戳/多时间戳、超采样、亚微秒级高速输入和输出以及微增量。这些子技术对于确保 XFC 系统的高性能和高精度起着关键作用。

时间戳/多时间戳支持将统一分布式时钟系统时间作为数据类型进行处理。该技术能够实时精确记录事件发生的时间戳。时间戳使得数字量和模拟量事件的记录以及输出设置都可独立于总线周期。例如,这样能够实现多个驱动轴之间以及与系统时间之间的精确同步。与单个时间戳不同,多时间戳允许在每个 PLC 周期内处理多个开关量结果。

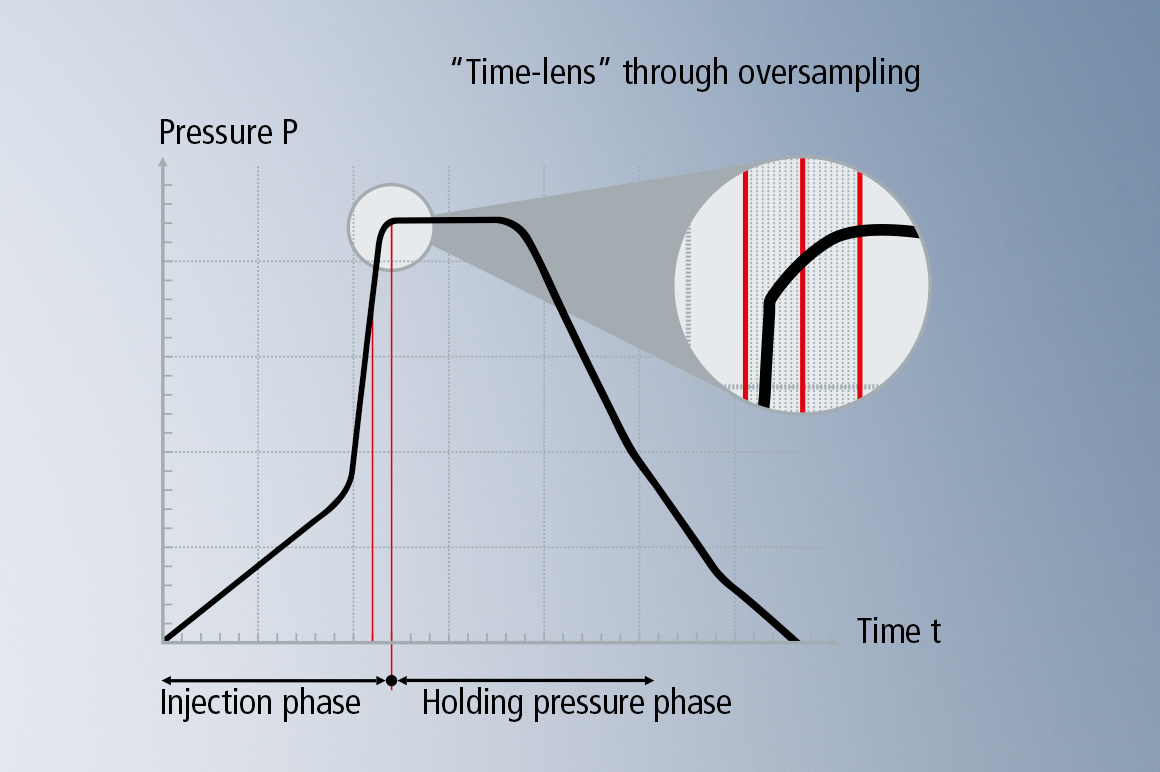

超采样技术可在不改变 PLC 周期的情况下,在设备端实现更高的采样速率。该技术通过在总线周期内以等时间间隔进行多次采样,并将测量数据打包传输。与标准评估方式(每个总线/控制周期 1 次测量)相比,高采样频率能够以更优的时间分辨率捕获信号,并可采集更高频率的信号。此类信号的传统检测方法需要缩短周期时间,但这会受到控制系统实际条件的限制。而超采样输出则可实现比周期时间更高的控制频率,从而在每个总线/控制周期内发出多个控制指令。

如果采用输入/输出延迟极低(<1微秒)的 I/O 设备,总线信号可直接转换为物理输出信号,反之亦然。再结合其它 XFC 技术,就能通过倍福标准组件实现最快的信号处理。若配合基于 EtherCAT 的高速现场总线通信以及倍福高性能工业 PC 的短控制周期,可以实现极短的响应时间。

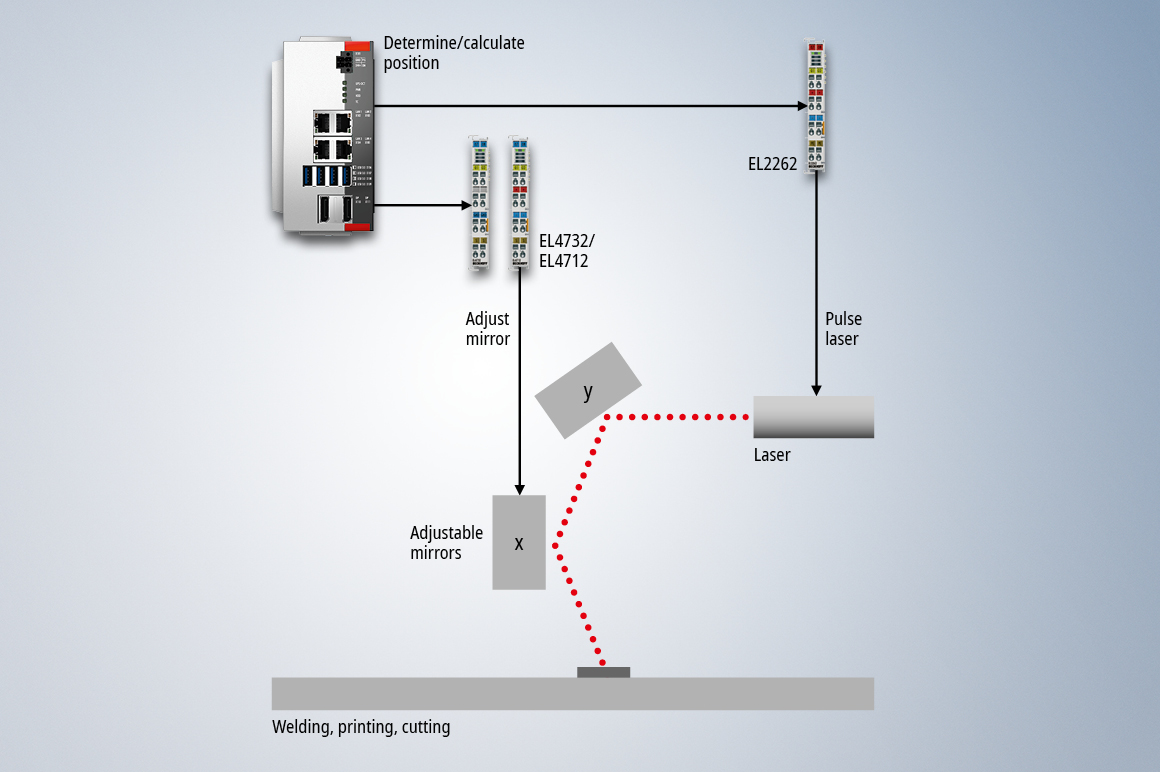

激光技术广泛应用于各种需要高精度和高速度的工艺过程。为确保性能,许多应用场景中都会采用 XFC 技术控制激光,通过分布式时钟将激光触发时间与光束校准进行同步。高更新速率是实现光束快速精准引导的关键。

为此,系统采用了具备超采样功能的 EL2262 数字量输出端子模块,它可实现时间间隔为 10 µs 的高速激光启停控制。激光束的校准通过两个电动可调反射镜实现,这两个反射镜分别负责 X 轴与 Y 轴 方向的定位。借助 EL4712 或 EL4732 输出的模拟量超采样电流信号,反射镜定位可保持与激光相同的高更新速率, 确保激光器在启停瞬间能够毫无延迟地从一个位置切换到下一个目标位置。

英国推出“2030 年全民风电”计划,即到 2030 年用海上风电为全英所有家庭供电。根据英国的电网数据显示,一月份某一天风电场的发电量达到了 19,835 兆瓦,足以满足英格兰一半以上的供电需求,充分证明了风力发电的巨大潜力。加大可再生能源的投资力度对全球实现 2050 年“净零排放”目标至关重要。Acteon 集团旗下的 Pulse Structural Monitoring 公司受委托为新风电场中所选的风机基础提供监测解决方案,整个解决方案,尤其是在整个设计过程中,使用了大量倍福基于 PC 的控制产品和 EtherCAT 测量端子模块。

德国泰克斯帕(TEXPA)机械有限公司位于德国萨尔州萨尔市,是全球领先的家用纺织品自动化缝纫设备制造商。为了让这些设备能够更好地满足客户需求,这家中型公司已使其系统尽可能地模块化。Texpa 公司的新型毛圈毛巾生产系统很好地说明了倍福基于PC 和 EtherCAT 的控制和驱动技术的开放性、灵活性和紧凑设计对于这些应用的重要性。

ContiTech 和 Continental Engineering Service 公司共同开发了两套输送带监测系统。这两套系统需要非常快速、高精度地记录和处理传感器数据。倍福的 EtherCAT 和 XFC 极速控制技术提供了一个高效的解决方案。

In order to protect against grid fluctuations, Korean engineering firm, Power21 has developed an Energy Storage System (ESS) for frequency control. EL3773 EtherCAT Terminals with eXtreme Fast Control (XFC) technology perform high-precision frequency measurements.

印刷业正面临着全球范围内的技术巨变挑战。全球所有工业印刷机运营商正在寻求一个进入数码喷墨印刷领域的契机。瑞士 Wifag-Polytype Technologies 公司成功开发了 Calmar — 用于各种商用喷墨打印头的工业级控制电子设备。Beckhoff 的 EtherCAT 和 XFC 极速控制技术为开放式高速控制平台提供了坚实的基础。

如今,激光熔覆技术通常用于涂装旋转对称部件。总部位于德国威斯巴登的 Ponticon 公司借助 pE3D 系统将应用范围扩展到任何几何形状的涂层和快速成型制造。如果没有倍福的 TwinCAT CNC、EtherCAT 和 XFC 极速控制技术,就很难实现对三脚架、旋转/摆动工作台和激光的精确控制和协调。

可靠的能源供应对于每个工业国家来说都至关重要。因此,中国海洋石油集团有限公司(简称“中国海油”或“中海油”)— 中国最大的海上油气生产商,非常重视海洋平台的监测工作。天津奥菱工业自动化科技有限公司(以下简称奥菱)受中海油委托,实施了支撑结构监测解决方案,旨在基于振动分析对承载能力进行可靠预测。他们采用倍福基于 PC 的控制技术和系统集成式高精度测量产品,以实现所有这些技术设备的互联互通。

PET 塑料瓶全球市场的巨大份额都取决于使用加拿大塑料行业创新者赫斯基注塑系统有限公司的机器生产的瓶坯。

汽车转向系统是关系到车辆安全行驶最关键的部件之一,因此也对开发时进行的系统测试提出了相应较高的要求。因此,总部位于德国科隆的 Akka DNO GmbH 与采埃孚股份公司(ZF Friedrichshafen Ag)合作开发了一款高性能硬件在环测试系统,该系统通过直接集成在倍福基于 PC 的控制技术中的高端测量技术采集所需的数据。