全面的机器视觉产品系列

作为基于 PC 的控制技术专家,倍福始终致力于将所有设备功能集成到同一个控制平台中, 这也包括图像处理方面,TwinCAT Vision 软件自 2017 年推出以来一直在完善。随着全面的机器视觉硬件产品系列的推出,倍福在这一领域的产品布局宣告完成。倍福 Vision 产品为设备制造商和最终用户提供完整的图像处理系统,其涵盖了从软件到光源等所有必要的组件,为用户带来显著的竞争优势。

系统无缝集成

- 相机

- 光学镜头

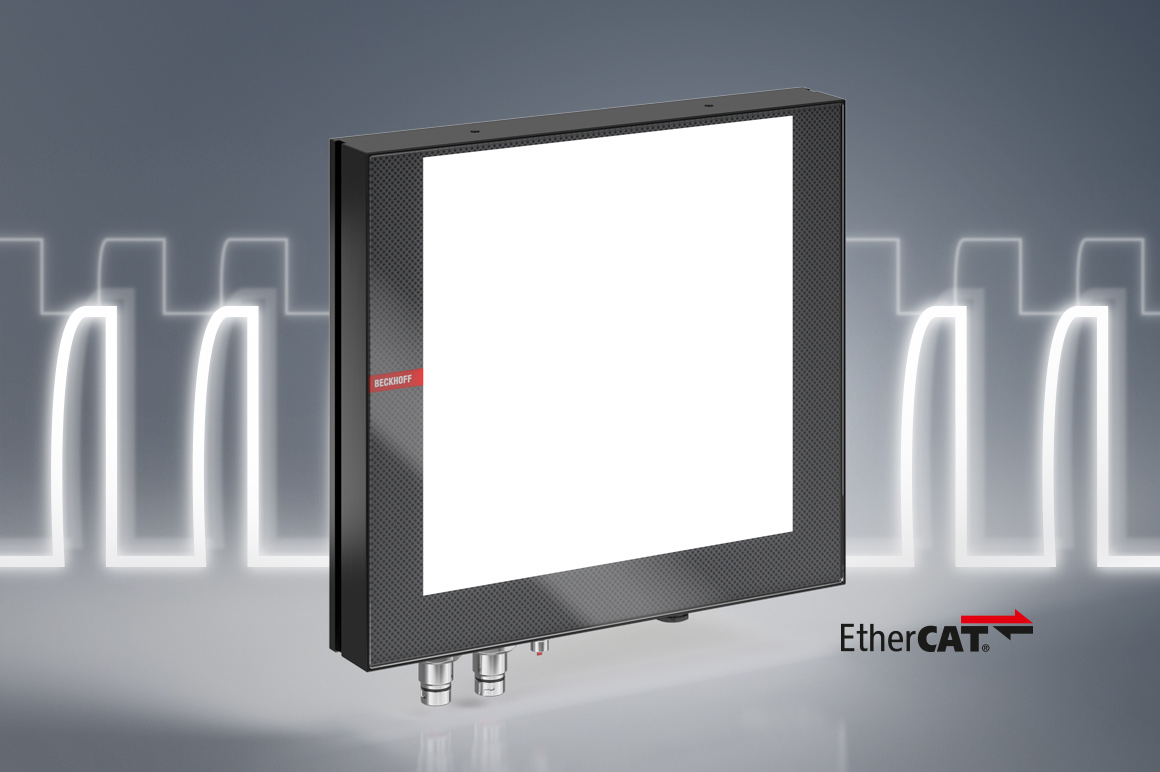

- 光源

- 完整视觉单元

- 软件

- 技术培训与支持

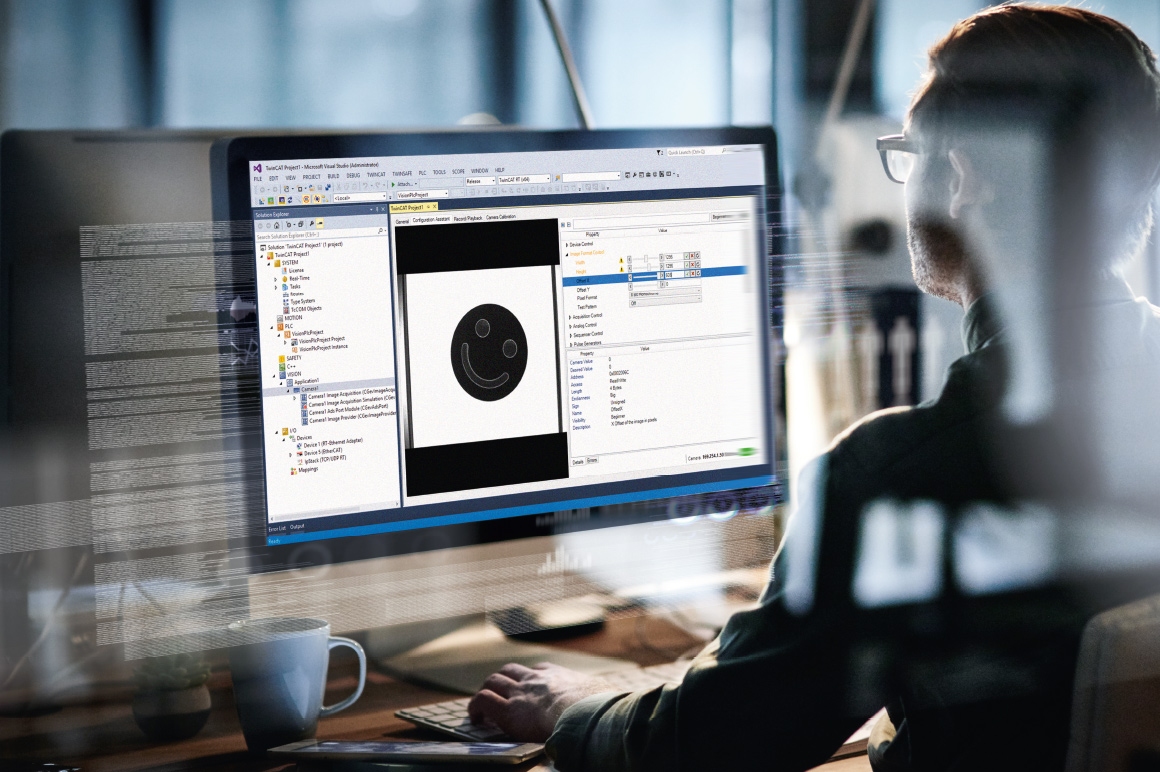

通过倍福 Vision 产品可将实时图像处理轻松集成到新的和现有的控制环境中,并与所有机器和设备流程优化同步。由于它们可以系统集成到所有应用环境中,进一步消除了以前机器视觉与自动化技术之间的严格分离。倍福 Vision 组件采用通用性强和灵活多变的设计,同时具有高可扩展性和长期可用性。

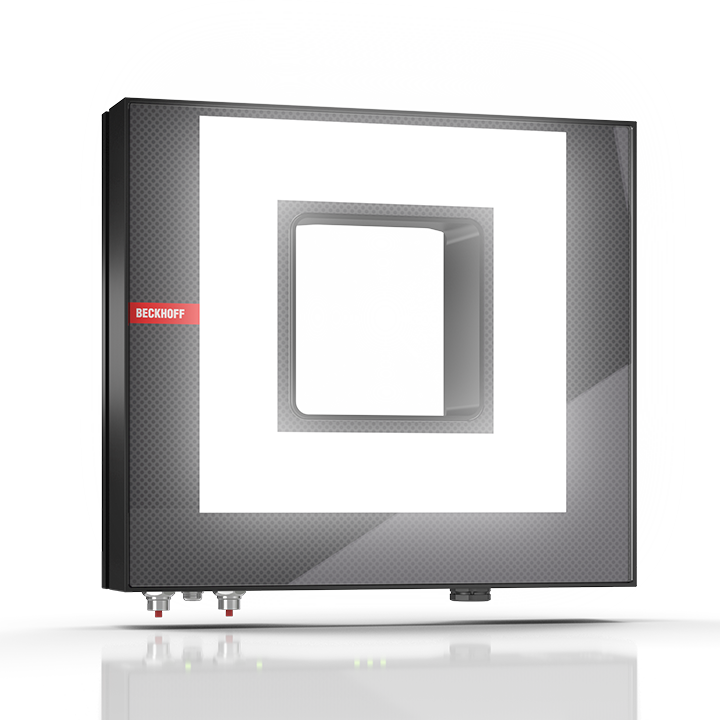

丰富的机器视觉硬件产品系列

主要优点

无缝嵌入到基于 PC 的控制系统中

- 支持成熟的国际 GigE Vision 标准

- 应用范围广泛,集成无限制

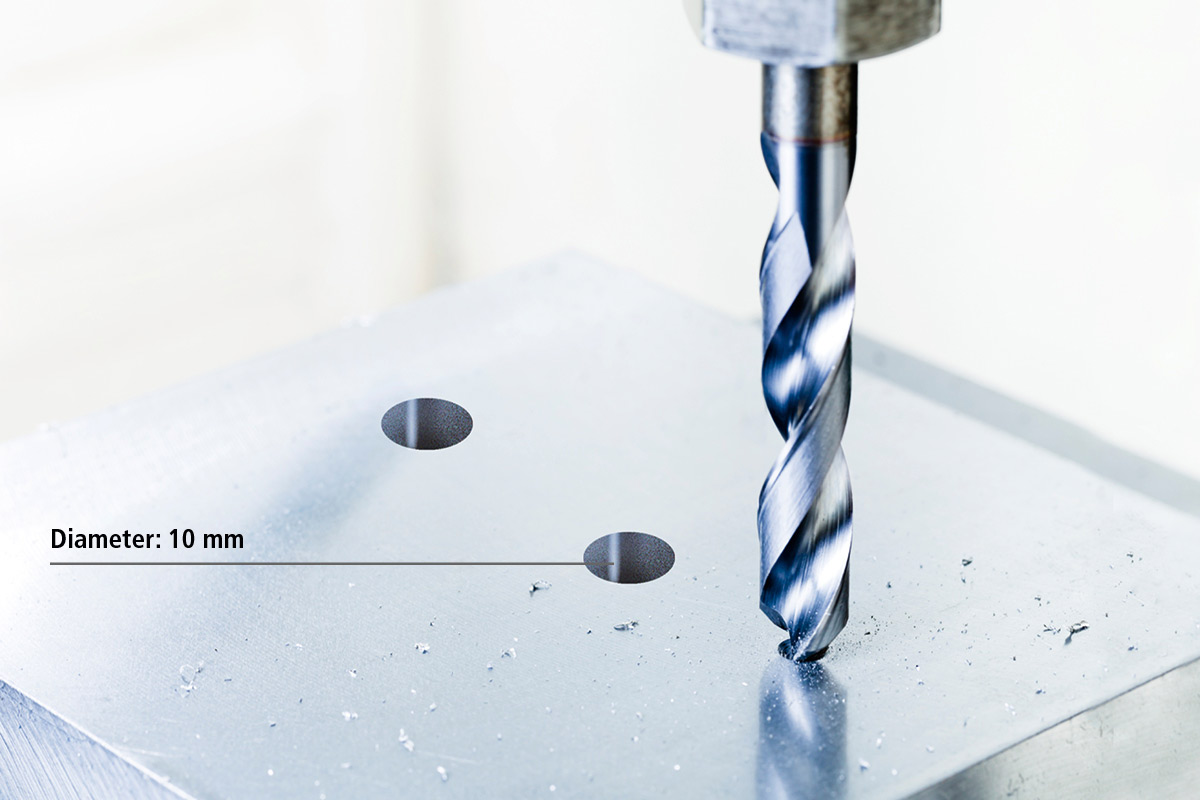

- 图像处理系统在相机、分辨率、光源和计算能力方面都具有可扩展性

- 由于采用开放式系统架构,因此能够简单地集成到现有的生产环境中

- 视觉配置方面具有极大的灵活性

- 可以根据不断变化的应用需求简单调整视觉解决方案和架构

- 组件更换方便

全集成在 EtherCAT 中,支持实时应用

- 简化和同步触发直接在系统中进行的图像捕捉和曝光

- 与所有控制过程和云服务器直接同步

- 缩短响应时间、提高生产节拍和加速处理程序

- 减少硬件和布线工作,缩短等待时间,减小安装占用空间和系统占地面积

- 简化诊断工作

融合不同的传感器结果

- 提升可靠性

- 确保可靠的评估结果

- 面向未来

- 开辟高级应用选项

- 打造竞争优势

适用于工业应用的出色技术设计

- 防护等级高达 IP65/IP67 的阳极氧化铝和玻璃外壳

- 光滑的玻璃表面对清洁剂以及其它化学品有很强的耐受性

- 拥有多种灵活的安装和应用选项

- 可选的防震保护

倍福自主研发和生产所有视觉产品,确保提供技术及质量一流的机器视觉解决方案。

- 一贯的高质量水平和功能性以及稳健的产品设计

- 依靠与领先的技术和组件供应商建立的长期稳定的合作关系

高精度控制和高效的电子元器件可以显著降低能耗

- 带分布式时钟功能的 EtherCAT P 单电缆解决方案和反应灵敏的电力电子器件能够与所有设备流程高精度同步,并有助于避免不必要的照明时间

- 蓝光 LED 芯片是高光输出和温度稳定性的基础,并可提高高温环境下的工作效率

- EtherCAT 控制的频闪模式减少了电源输出以及所需的散热工作,同时降低了光源的能耗。