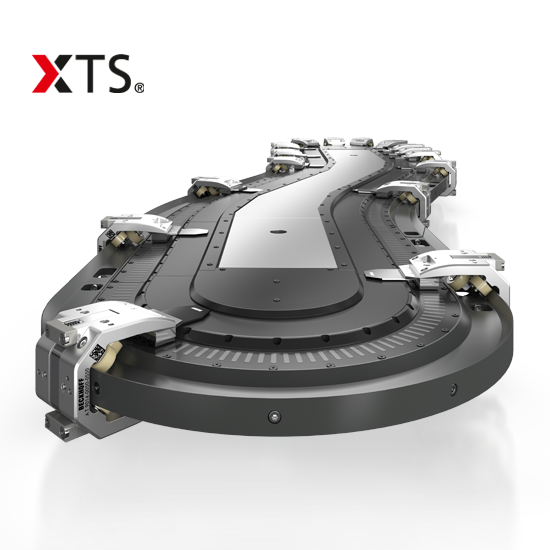

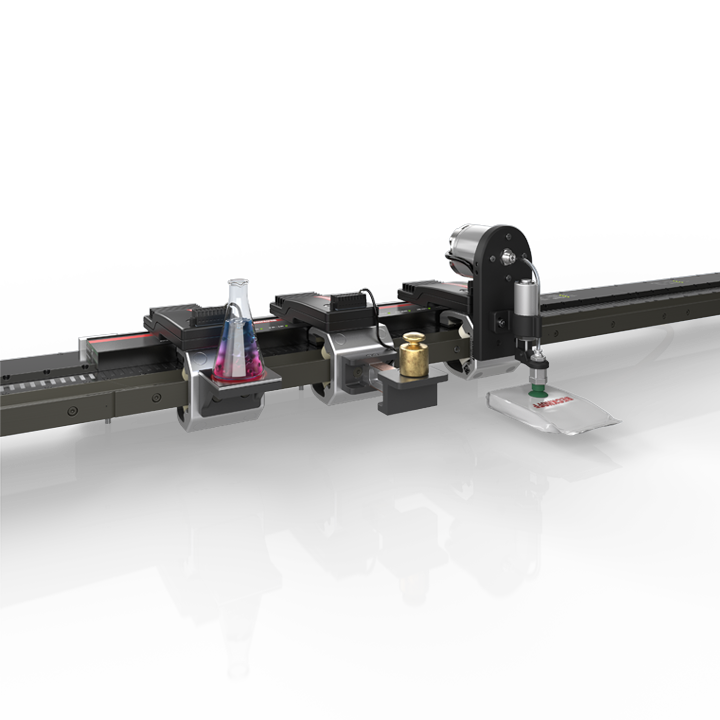

企业该如何借助自动化来获取竞争优势呢?我们将以 XTS EcoLine 电机模块为例展开说明。在相同的传输距离情况下,XTS 系统的电机模块仅需原先大家所熟知的电机模块 55% 的成本,就能实现其 95% 的性能。

更多关于此视频的信息

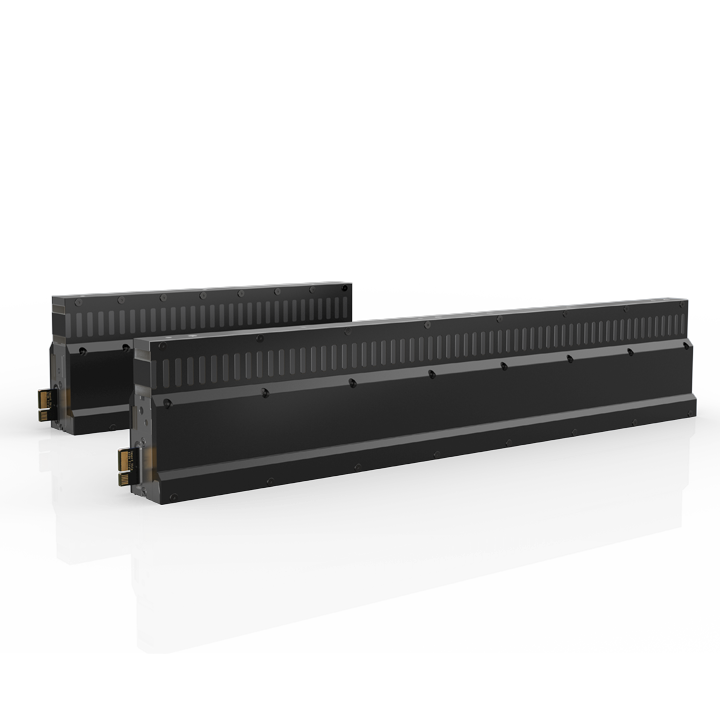

AT2202 | EcoLine motor module, straight, with plug connector for infeed

The AT2202 motor module is very similar to the AT2200 motor module. In addition, it has a connector for supplying power and communication, which connection cables in variable lengths can be connected to. Compared to fixed connection cables, the connection cables are drag-chain suitable and longer cable lengths are possible. With a length of 500 mm, the motor modules with infeed represent an economical alternative to standard motor modules in applications that do not require the highest level of accuracy. By attaching motor modules without infeed, straight and curved track layouts, the infeed line can be extended up to 3 m. An entire XTS system consists of at least one infeed line. Several infeed lines of different lengths can be used in one XTS system. The length of an infeed line is primarily determined by the mechanical motion profile of the movers and thus the electrical power consumption and the number of movers on the respective track.

AT2200 | EcoLine motor module, straight, without infeed

The AT2200 motor module is an element for setting up straight XTS track sections. Simply plugging them together establishes an electrical connection between these motor modules. With one power supply, a maximum of 6 motor modules can be plugged together one after the other in a 3-meter long power supply segment. The standardized 500 mm length enables finely scalable system lengths. The EcoLine motor module is an economic alternative to standard motor modules for applications that do not require the highest level of accuracy.