采用卫生型设计的磁驱柔性产品输送系统

在严苛环境下仍保持灵活高效

中国区总部

毕孚自动化设备贸易(上海)有限公司

+86 21 6631 2666

info@beckhoff.com.cn

www.beckhoff.com.cn/zh-cn/

在严苛环境下仍保持灵活高效

卫生型 XTS 系统是专为卫生与清洁要求极高的应用场景量身打造的智能输送解决方案。该磁驱柔性输送系统可应用于食品和制药行业的主要环节,以及液体产品的制造与灌装流程,具有耐化学腐蚀、易于清洁的特点。

XTS 系统在打造创新型设备方案中所展现出的、广为人知的显著优势,在卫生型 XTS 版本中同样得到了充分体现:

该产品输送系统在完成组装后,防护等级高达 IP69K,同时采用卫生型设计,无任何隐蔽死角和凹槽,可依据行业标准便捷高效地完成清洁工作。卫生型 XTS 系统由经过电解抛光处理的 1.4404(AISI 316L)卫生级不锈钢制成,并配备耐高压清洗的 VMQ 硅胶密封件,符合欧洲卫生设备设计组织(EHEDG)认证标准。经实验室测试验证,该产品对行业标准清洁剂具有良好的化学耐受性。

整个系统可耐受化学品和腐蚀性清洁剂,并能进行高压清洗。它符合 EHEDG 标准要求,且配备卫生型 XTS 的系统可由用户根据 EL Class I AUX 标准进行自认证。

卫生型 XTS 系统在技术上与标准 XTS 系统极为相似,除具备卫生方面的优势外,还拥有 XTS 系统的所有核心优势:

卫生型 XTS 系统集高效率、高精度与卫生标准以及灵活性于一身。

卫生型 XTS 系统的电机模块从设计之初就专为在严苛环境条件下使用而打造,其不锈钢外壳可为电子元器件提供有效防护。

用于供电和通信传输的插头触点都在侧面,因此模块的连接也特别简单。一个带有必要连接触点的盖板能够牢固连接两个电机模块,同时也可用作供电点。因此无需拆卸电机模块,即可灵活调整供电点位置。

卫生型 XTS 系统的电机模块采用不锈钢材质,且无任何隐蔽死角、棱边或凹槽,便于清洁。模块间及所有螺丝连接点均采用卫生级密封件,可有效防止液体渗入。所有电源和数据线缆均敷设于密封保护管内,其表面具有抑制防止微生物生长的特性。

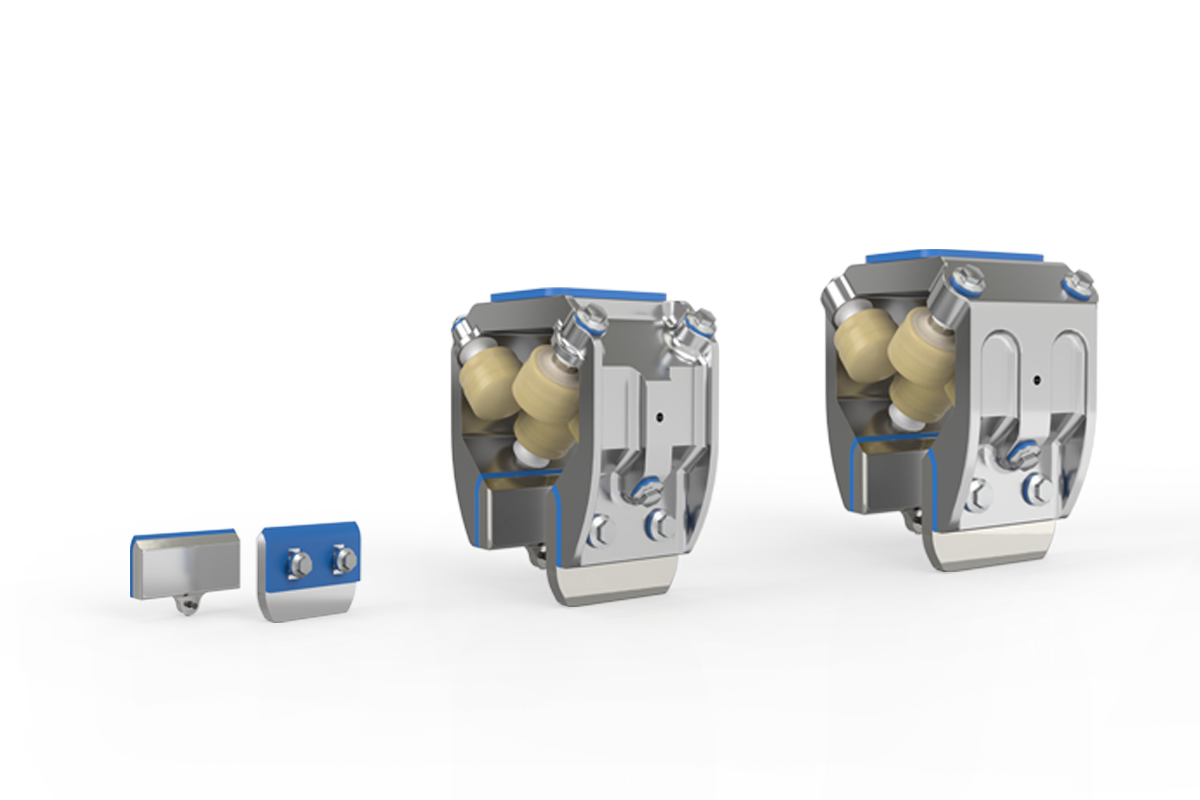

可单独控制的动子同样也是卫生型 XTS 系统的核心组件。它们采用不锈钢或铝合金材质,具备出色的耐久性。

其流线型外形设计便于清洁,即便在对污染特别敏感的环境中,亦能满足严格的卫生标准。

采用卫生型设计的永磁体组可作为独立组件,适配第三方动子。

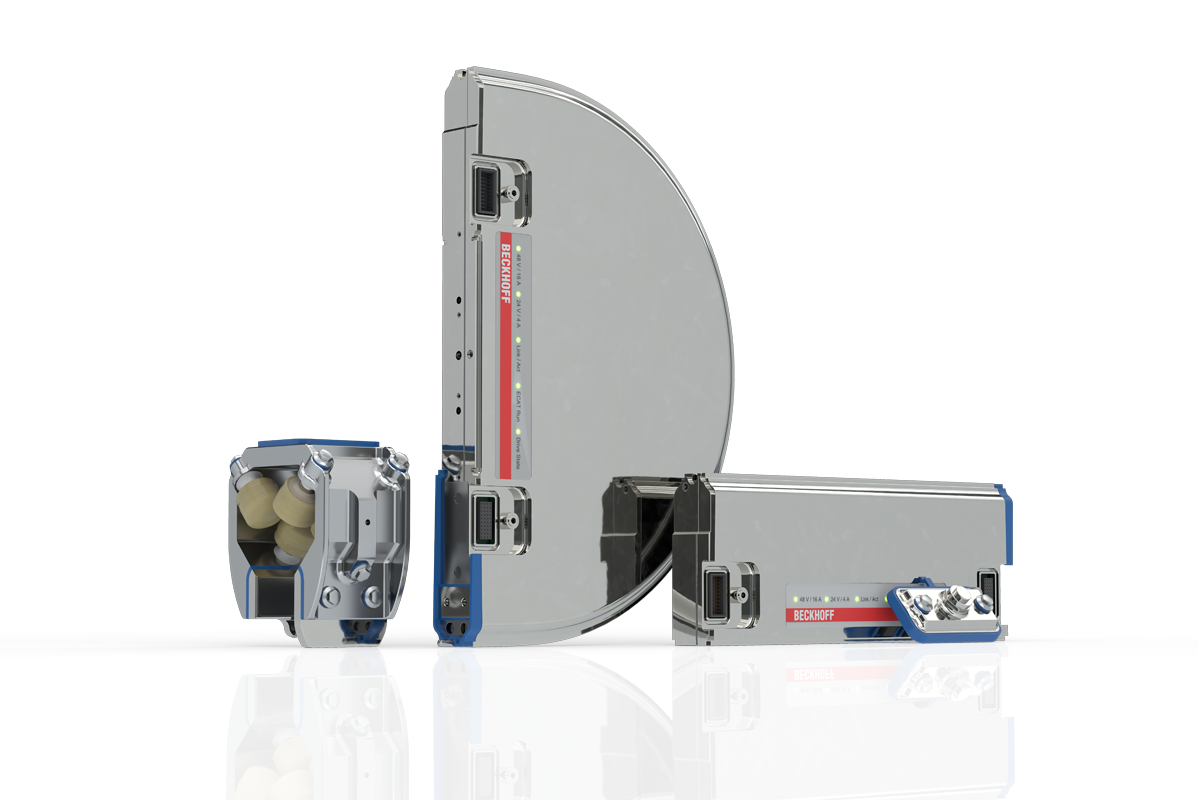

ATH200x 电机模块是用于构建 XTS 直线轨段的元件,适用于严苛环境条件。由于用于电源和通信传输的插头触点都在侧面,借助盖板即可轻松实现电机模块间的连接。该盖板包含了连接两个电机模块所需的触点,并可选择配备一条供电电缆,以便用作电源接入点。无需拆卸电机模块,即可重新定位供电点进或调整供电设备的数量。

ATH205x 电机模块是用于构建 XTS 曲线轨段的元件,适用于严苛环境条件。 它们是采用回旋曲线几何形状的 180° 外曲线段。由于用于电源和通信传输的插头触点都在侧面,借助盖板即可轻松实现电机模块间的连接。该盖板包含了连接两个电机模块所需的触点,并可选择配备一条供电电缆,以便用作电源接入点。无需拆卸电机模块,即可重新定位供电点进或调整供电设备的数量。

卫生型 XTS 系统动子和电机模块及导轨形成最佳匹配。它们有两种不同材质可供选择:一种是不锈钢动子,用于对卫生要求特别高的环境条件,另一种是阳极氧化铝动子,可以输送更大的有效载荷,比不锈钢型号的动态性更高。动子的设计和材料使其能够在清洗机中进行清洗。编码器尺集成在全封闭的动子磁板组之上。客户专用的附件和工具安装可通过随货交付的密封件安装在动子上,以确保在连接客户设备时也能满足相同的卫生要求。

AT9001 磁板组是 AT90xx 动子的一部分。如果导轨需搭配第三方供应商提供的动子或自行设计的动子使用,则可单独选购磁板组。XTS 电机模块产生的行波磁场借助磁板组件实现直线运动。每套磁板组包含两块磁板。其中一块磁板装有坚固的编码器标尺,可以实现动子的非接触式位置检测。