Products

Modular design concept for maximum flexibility

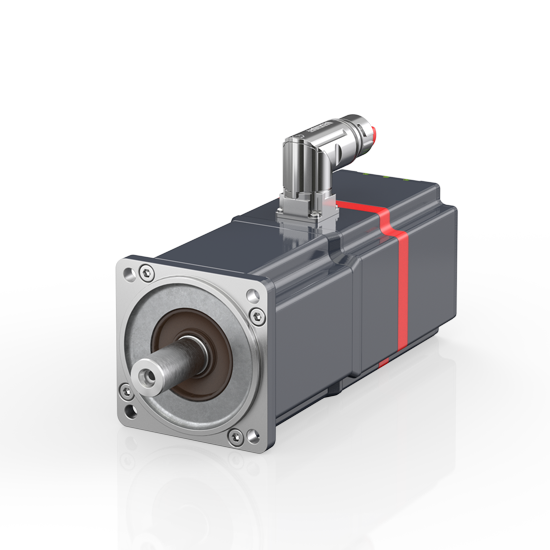

The AMP8000 distributed servo drive system opens up new options for modular machine concepts: the AMP8000 integrates the servo drive into the servomotor in a very compact design. By placing the power electronics directly on the machine, the control cabinet only needs to house a single coupling module, which supplies several distributed servo drives with just one cable via a distribution module. A further expansion stage means that zero control cabinet space is required for the drive technology. Whereas the drives are connected to the control cabinet with just one cable with the coupling modules, this connection is completely eliminated when using the AMP8620 power supply module. This all results in significant savings in terms of material, installation space, costs, and installation work.

More compact motors, fewer cables

The EtherCAT P one cable solution forms the universal basis for wiring the distributed servo drive system. EtherCAT P combines communication and power supply in one cable. Only one cable type that is identical for all components is needed to wire the entire AMP8000 servo drive system. The entire system can be cascaded, so that even complex machines with a simple topology structure can be created. The EtherCAT P one cable solution greatly simplifies logistics and minimizes wiring errors. The cable trays to the motor become clearer and the space required in the control cabinet is reduced to a minimum.